The biggest shock for me was the sheer quality of the tools on offer. When I first held a Bergeon screwdriver in my hand the feeling was so different from anything else I had ever used. I don’t think we should be allowed to use the term “screwdriver” to describe both the cheap sets that you see at model shows and a really good Bergeon screwdriver. I think they should be named something different like “rotational screw implement”! I wonder what term Ron Dennis would think up for it?!

Let’s start with the basics. First of all, the cheap screwdrivers you get at shows are generally not ground at all. They are just stamped out of rod to a general blade. There is very little precision in their manufacture.

A Bergeon screwdriver blade is beautifully ground to the correct shape for the screw that it fits. This means that there is far less pressure needed to remove the screw and because of this there is far less chance of damage to the screw or the model. The Bergeon blades are also available separately and the handles are fitted with a grub screw to make replacing them easy.

The blade is retained with a grub screw so you can replace it when it wears out. But spare blades are readily available in little packs of 3. The decorative lines are not just there for show. They also indicate the clamping position for the Bergeon sharpening jig. Unfortunately its rather expensive and I don’t have one…..

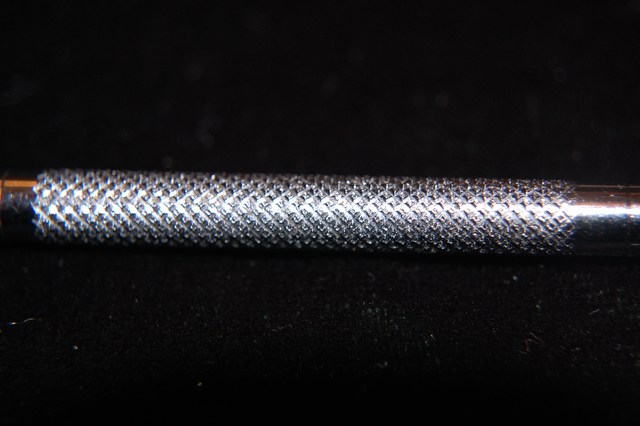

Moving up to the handle, the cheap screwdriver is generally machined from a piece of metal that was extruded with a ribbed pattern around it. Sometimes this has been stamped on later. The purpose of this knurl is to provide grip. But it shouldn’t feel course or rough.

The Bergeon handle is machined from rod, and then chromed. The knurl is cut on the lathe and the result is a handle that provides the appropriate grip but also feels smooth and pleasant to use.

Moving up to the top of the screwdriver, they both have revolving heads, but while the cheap one is simply pressed on and is rough when you turn it, the Bergeon has a smooth Teflon bearing or even a ball race on the larger models.

The correct way to use a small screwdriver is to have the revolving head pressed against your index finger. This provides all the guidance.

To rotate the screwdriver, use your index finger and middle finger. This maintains a constant pressure. To steady things more, you can use your ring finger or little finger to steady things. Don’t use those ringers to give rotation. Leave that to the thumb and index finger.

There is a downside to this. A Bergeon screwdriver will set you back about a tenner. I suspect you could find 100 Cheap screwdrivers for the cost of a single Bergeon!