About 2 years ago I ran into a fairly major problem. I broke a Swiss file that I use every day in my hobbies. I had anticipated a simple call to the place I brought it from would see a new one popped in the post and an end to my problem but that was not to be. Over the next couple of weeks I learned a huge amount about files.

I found that allot of what had been written was very good but a little dated so here is my attempt to bring it up to date.

First of all I would like to draw your attention to an excellent article on the 2mm associations website that explains the technicalities of the Swiss file. I think this article should be compulsory reading for anyone getting into more serious modelling!

A few years ago it was fairly easy to get good quality tools. But in recently the huge influx of cheap tools from Asia has had a massive effect on supplies.

I want to echo what Andrew Webster said in the above article that these cheap files are really terrible tools and are not really fit for purpose.

The file I broke was marked “Grobet Vallorbe”. I have since found out that Vallorbe is actually the manufacturer and Grobet USA is the outlet in the US. My file had been manufactured in Switzerland, shipped to America, then shipped back and sold by Squires for about a tenner.

When I spoke to Squires they said that the change in currency value had made the cost of importing them from the US prohibitively expensive.

I posted a message on Modelrailforum.com and there were some positive replies but only suggesting Ebay.

I have not had much luck with Ebay and when I am buying a quality tool I really want to see it before buying. There is a feeling you get when you are holding a really good quality tool that is almost indescribable, you can sense the potential of what it can create. If you don’t know what I mean try going into Debenhams, picking up a cheap knife and then going and trying a Sabatier knife- you will know what I mean.

As they are Swiss files I then set about sourcing them from there. I found the website for Vallorbe and found that they make a huge range of files for every task you could possibly imagine. If you want to file the wings off a 747 then they probably have just the tool for you! They also do files for jewellers. I am going through a phase of doing a little bit of jewellery making so I went on the web and had a look for Jewellers supplies and suddenly came across Hatton Gardens. An entire district of London less than 20 minutes walk from my home that is totally devoted to selling me decent tools!! I went along and had a look and found a couple of shops that might be of interest to modellers.

The first is Rashbel they are a nice small shop. Very friendly but with a touch of Camden about them. They feel slightly rebellious amongst the formality of the other shops in the jewellery district. The staff are very helpful and don’t mind you having a browse. In only 3 weeks they have become a regular haunt of mine. They have a good selection of tools and a huge selection of mini drill tools, slitting discs and polishers. (I want to point out here that allot of minidrill tools that are sold to modellers come with 1/8th shanks. Jewellers tools have a 2.4mm shank so I have found myself changing collets allot in the last few weeks. I will revisit the minidrill in another article)

The second shop I went to was H.S.Walsh they feel like the more corporate end of the market. Their showroom was full of the same high quality tools but it felt a bit more like machine mart than the dusty friendly feel of that imaginary hardware store we all have in our minds.

Cookson precious metals was next on my travels. I had seen their website and they have a vast range. The shop really felt like a place for jewellers rather than a hobbyist I felt a bit out of place. For a start I really want to see and feel what I am buying. In Cookson you have to go and get a number and wait your turn then go to the counter and show them the numbers you have written down off the internet. I am sure they would be friendly if you went in there not really knowing what you were buying but I felt very self-conscious holding up all the other people waiting in the queue. Despite their vast range of tools I suspect that I will not be spending much time in Cookson in the future.

The last shop I went in was Lynco Their website felt a little strange but they had some tools so I went and had a look. It was really a store selling jewellery packaging and although they had a few tools I don’t think I will bother next time. They are a really good shop but they are not really selling what I wanted to buy.

I came away with 3 files and the 2 I had for Christmas from my father make it 5. by far the nicest is a file I got from Rashbel. It’s a 20cm half round. Before Christmas I didn’t even know that 20cm files existed but there they were on the shelf! If I am holding a Swiss file for a long time I start to get cramp in my hand and the slightly larger handle of the 20cm makes it much more comfortable to use. The longer surface also makes the act of filing a bit quicker and it feels more precise because you have more control over the bigger tool. Mine is a No4 cut which is a very smooth file and perfect for precision work but slow at removing larger amounts of material.

I got a No2 half round file (an ordinary 16cm) for Christmas and it’s much better at removing more material that 7mm scale requires. Removing the etching cusp from a 7mm chassis with the number 4 cut would be a real bore! But a no2 cut is about perfect. I have a parallel file (a continuous rectangular section) that is a No0 cut and its just too course. I thought it would be great but it feels like its snagging the metal rather than gently cutting it away. I would not recommend the 0 cut. I have also found that the parallel file feels allot more flexible than the half round.

The round file I use is a 2 cut. This is the survivor from the original pair I got about a year ago and it’s one of those tools that tends to sit in the drawer for 95% of the time but is perfect for that job when I need it as opposed to a tool I use every day.

I also have a no4 16cm half round but in just 2 weeks is been largely superseded by the 20cm version.

I have files of 4 different makes. But I have a strong suspicion they have actually all come from the same factory. But for reference, names to look out for are Vallorbe, Grobet, Baiter and Glardon.

I am often asked about keeping them clean. I have never found a satisfactory way of keeping them really clean. By far the best method is not to get them dirty in the first place! But in some instances, there is really no option. I do occasionally work in whitemetal and that clogs them so easily. I have particular files that I only use on brass. Party so they stay reasonably clean but also because I know they will not have any steel particles on the surface that would scratch a brass or nickel silver workpiece.

For really stubborn bits of whitemetal, I just pick away at them with a knife… But for general cleaning, I have an old Peco wheel cleaning brush that is far better at cleaning files than it is at cleaning wheels!!

I also have 1 file that’s a bit of an imposter. It was made by an English company called Stubbs. It looks pretty much the same as the others except its about 30 years older! Amazingly from what I have read, I don’t think Stubbs actually cut their files. They produced the blanks and the cutting was carried out by cottage industries in their sheds and garages in the north of England. I also have a couple of uncut blanks tucked away that are also stamped with the Stubbs name. This file has been in the family for as long as I can remember. It was used extensively on the garden railway when I lived in Gloucester over 15 years ago and it still does occasional service but for most of the time, it sits in the rack as a curiosity and a reminder of Britain’s industrial heritage.

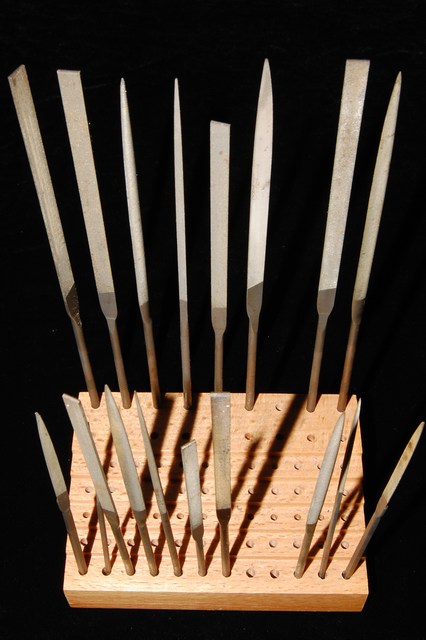

Looking after your files is very important. It’s far cheaper to look after a good set of files than it is to replace them! I keep mine in a burr stand that I have drilled out some of the holes to match the handles of the files. The smaller Escapement files have handles that are thinner than the 2.4mm burr shanks so at some point I will get some plastic tube to make the fit a little tighter.

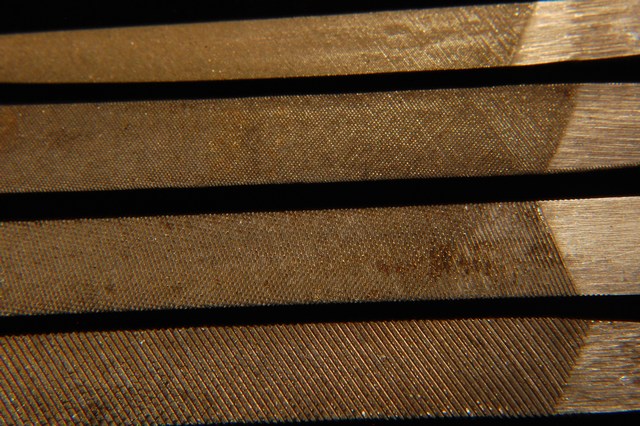

Here is a comparison for you of the grades of file I use.

From bottom to top, grades 0,2,4 & 6.

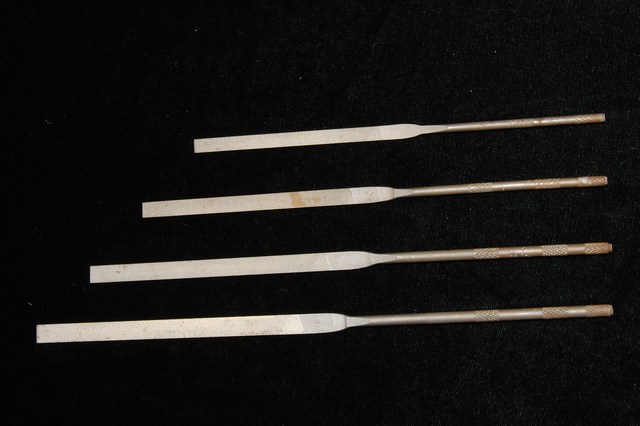

As I am sure you are aware, files come in a multitude of shapes. My favourite is the half round, but here is a selection. From bottom to top, Flat (sometimes called pillar), half-round, Square and Knife.

This next picture gives you an idea of the various sizes available. From bottom to top, 14, 16, 18, 20cm. the size makes a huge difference not just to the working area but also to the balance and feel of the file.

Since writing the above article I have expanded my range considerably but Stuck to what I said above. I do really like the 20cm files that I mentioned. But for work on a couple of 009 and HOn3 loco's I even invested in a couple of escapement files that are very fine indeed (no.6 cut).

The escapement files

I am still amazed that it’s made such a difference to the way I work. In the 2 years since I wrote that article they are still a pleasure to use.