Well, I suppose I should start with drill bits! For my purposes, they come in a few different flavors. The ones I use 99.9% of the time are the Precision Twist Drills made by Busch. They have a standard 2.34mm shank that will fit all mini drills, and is particularly useful if, like myself, you happen to have a nice pendant motor with a quick release handpiece!

The working portion of the drill bit is about 10mm long.

When I first discovered these bits, the number of breakages went down by about 80%! Expect to pay in the region of £10 for a pack of 6.

By biggest criticism of these bits is the lack of small sizes. The smallest size available is 0.5mm. which might sound small, but I frequently have a need to drill holes smaller than that and a 0.4 and 0.3 size would be very welcome!

Busch also make the same drills is HSS (High Speed Steel) and if you are feeling REALLY flush… Solid isostatically compressed carbide!

I have tried the Carbide drills. I found them very unforgiving. They are incredibly strong and retain their edge very well. But the slightest misuse (which is inevitable with a hand held drill) they are very prone to breakage. If you happen to have a very sensitive drill press, then do give them a go. I would be very interested to hear how you get on.

I do have a few of the HSS bits. For my use, I find that the only real difference when using them is how hard it hits your wallet when you break one!

Simple twist drills are available in a huge range of sizes in 0.01mm increments. As with all drill bits, buy quality. It will give far better results and the amount of time you will NOT be spending trying to remove broken drills is not inconsiderable! Remember your time has a value!

Ball drills.

These are the unsung hero of mini drills! Many people think they are just burrs, but they can do so much more. To start with they have far more cutting edges so the finish is far better. They are also available down to 0.3mm! (Although the smaller sizes can get a bit expensive!)

Burrs

Again, available in a huge variety of shapes and sizes. Mostly aimed at the jewelry industry for setting stones but also for every other purpose under the sun!

I tend to use them for 2 distinct reasons…. Firstly the smaller ones are very good for what I like to call subtractive modelling (especially in the smaller scales, it’s sometimes more convenient to attach a larger piece of metal then file or carve it back until it’s the right size.) where precision is needed but hand tools are sometimes impractical.

The larger sizes are great as rotary files and are particularly useful when removing large quantities of material.

It is extremely important to use proper lubricant (more on that later!)

One shape of burr that I do want to draw your attention to is the cup burr. They are perfect for rounding off the ends of wire. If you are trying to pass the ends of a piece of wire through a difficult to access hole, butting a dome on the end can make life so much easier.

Diamond burrs are useless for our purposes. They are designed for drilling through stone or carving soft stone and are worked immersed in water. They are not designed to work with metal. They will clog too easily. They sound like a good idea because they are made from diamonds, but leave them with the stone workers and stick to metal working tools.

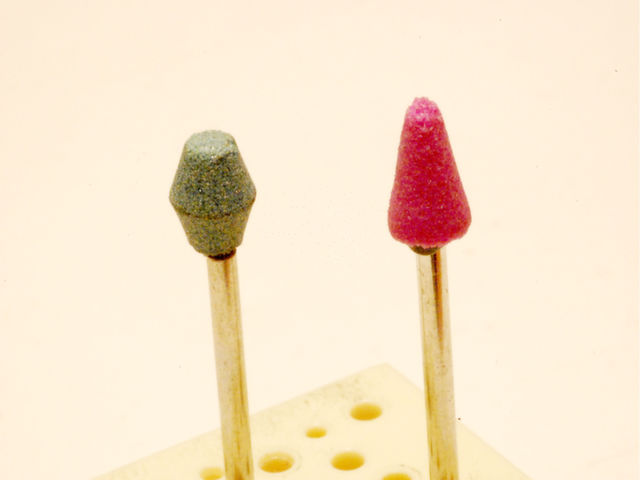

Grindstones

These are bundled by the dozen with cheap drills and come in every shape and size imaginable! I find them mostly useless. If anything I find them more for general DIY around the house than on the modelling bench.

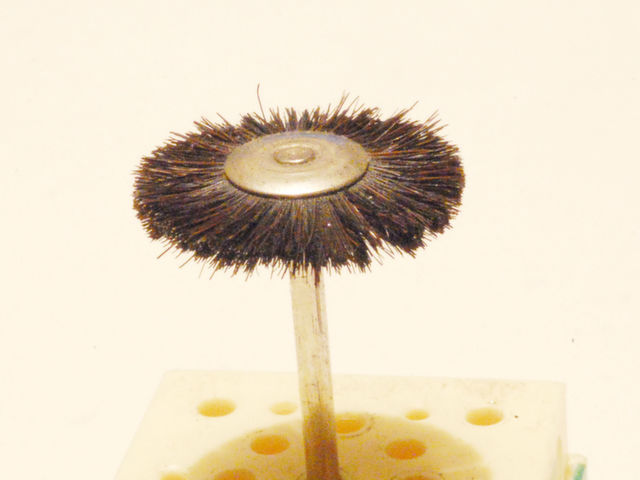

Rotary brushes

Available in 3 shapes. Each in Nylon, Brass and Steel

Cup-This shape, I find virtually useless. I think I have had it sitting here on my bench for 5 years + and I have only found a use for it once.

Pencil-Mildly useful. Especially in tight spaces. I don’t tend to use it because although it does a good job, it leaves a greasy residue that can be more difficult to remove than the thing I was using it to remove (I think that makes sense!)

Wheel-Extremely useful! The beauty of the brushes is that the brass and steel wheels, if used carefully, can remove solder and flux residue without disturbing underlying detail. So if you have made a bit of a mess of that overlay you were working on, this can be just the thing to tidy up the mess!

For all the brushes, again buy quality. Expect to pay about £1.25 per brush

Rotary saws

These are EXTREMELY DANGEROUS. I don’t think it’s any exaggeration to say that these are potentially lethal. I don’t think they should be sold to the public.

They do have their uses. For example, I use them as a rotary file when removing larger quantities of whitemetal as it doesn't seem to clog anything like as easily as a file or burr.

BUT they do snatch on anything and everything. And if your finger is in the way when it does snatch then its goodbye finger.

My advice is to leave these well alone. There is always another way to do the same job. The alternative may not be as quick as the rotary saw, but it will surely be ALLOT safer.

Rubber abrasives

These are fantastic! Available in various grades. They tend to be colour coded but I won’t list the colours here as it tends to depend on the manufacturer.

The finer grades are perfect and impart a good polished look almost effortlessly. Be careful because they sometimes leave a greasy residue and do cause allot of heat. Little and often is the trick.

The courser grades are one of the most useful mini drill accessories. They effortlessly remove solder overspill and if used carefully, won’t damage the underlying brass. I use these allot when I am building coach chassis. I just find it easier to overdo it a little with the solder and then remove it with one of these.

99% of the time I use a shape called a “Saturn” of a “Knife Edge”.

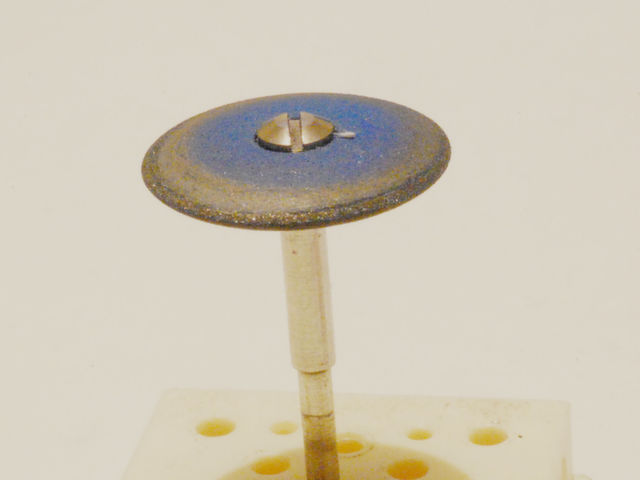

Abrasive discs

Everyone if familiar with these! But they are not all created equal! The cheap ones that normally come free with cheap drills are really not good for much. In fact I normally just give away those to friends when they are running short. For myself, I use 2 flavours. The first is a thin carborundum disc about 22mm in diameter.

If they are not abused, they should wear out long before they break. But if knocked against something, they will shatter very easily!

The second is a larger carborundum disc. About 2” in diameter. I used to use this allot. And it was particularly useful down the club when the thinner discs would get broken too easily. The cut is much thicker, but they are very good when building pointwork. Just rest the rail against the disc for the neatest point blades you have ever seen!

Diamond discs are also available. I have one sitting here on the bench. I rarely use it. I think it has been of more use to my father when he kept breaking the carborundum discs. In fact, if you can’t keep your discs in one piece then this could be the perfect solution for you!

There are also fibreglass reinforced discs. I have a couple tucked away. When cutting, I have enough problems keeping grit out of my eyes and off my machines without fibreglass getting involved!!

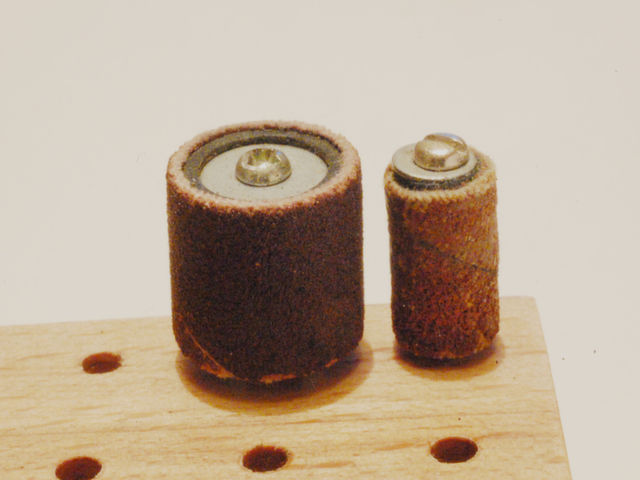

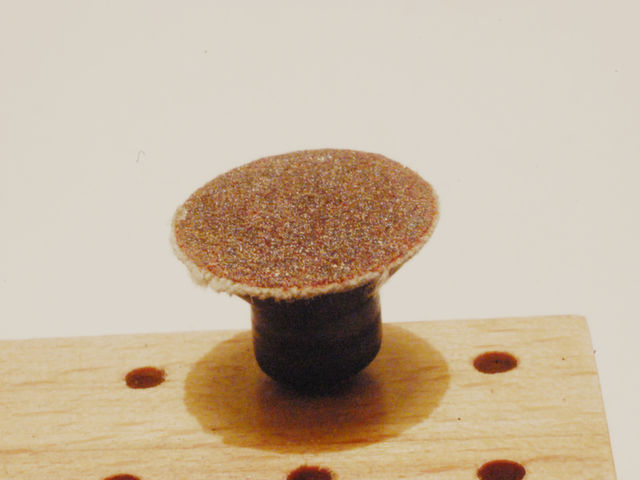

Sanders

I use 4 different sanders. The first 2 are bobbin sanders. I used to use these an awful lot, but these days they have more or less fallen out of favour. They were particularly useful when working whitemetal. But as I don’t work whitemetal very much these days….

The third type is the flat sander. In my opinion this is one of the most important mini drill accessories. But is surprisingly difficult to get hold of these days. The principle is very simple. A self adhesive disc on the top of a flat rubber pad. Perfect for removing material in both hard to reach places and also for large flat areas. I tend to use it in areas that will not be visible on the model because the finish it leaves isn’t that great.

The 4th type of sander is similar to the flat sander. But has a clip to attach the disc. This may sound great (no more discs flying off into the ether!) but it does have a side effect. The clip can leave bad scratch marks if it comes into contact with the work. I don’t really like to use this tool. But when nothing else can get in the space, it does have its uses. The disc can also be reversed to face down. This can be useful if you are trying to get under something.

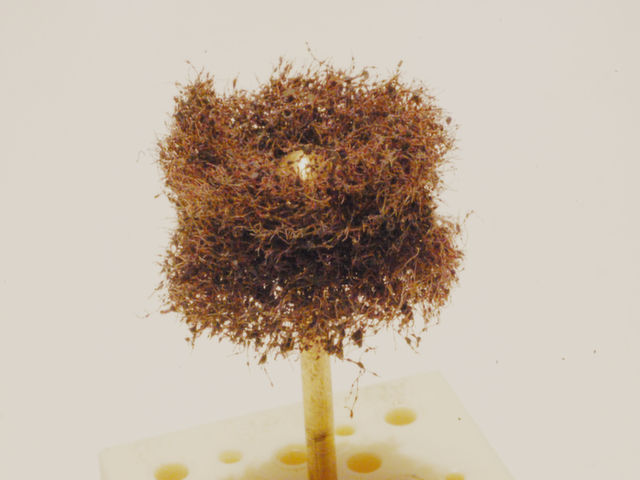

Scotchbrite wheels

A fantastic invention! They are a synthetic wire wool on the end of a mandrel. I use these all the time to give my models a brushed metal look that I love. They do wear out pretty quickly but can remove solder and flux residue and clean up tarnished brass in seconds without destroying surface detail like etch lines and rivets.

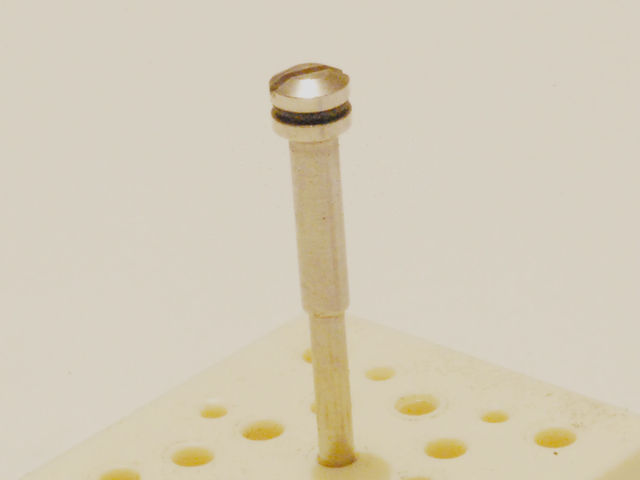

Mandrels

Mandrels are not all created equal. A decent quality one is far superior to the cheap ones that come bundled with a cheap drill.

Look out for one with a properly machined screw that matches the body. Not one that just has a standard screw in the top with any old washer. The fibre washer is a good idea but remember to put it on the screw side of the disc and not on the body side. The body has been machined true and so the disc should sit flat against it. The washer goes the other side to iron out any irregularities with the screw.

Lubrication

A final little word on lubrication. Drills and burrs will last far longer and you will reduce breakages by simply using a proper lubricant. I use Pro-Cut and the little pot is ugly but its been going strong for about 5 years and I have only used about 10% of it!

WHEN USING POWER TOOLS OR SOLDERING, MAKE SURE YOU ALWAYUS TAKE PROPPER SAFTY PRECAUTIONS. ALWAYS WEAR SAFTY GLASSES AND BE SURE TO WASH YOUR HANDS AFTERWARDS.