Keyser Kits hold a special place in the hearts of many modellers. For many of us they represent our first introduction to kit building. Also an introduction to many new techniques. Whitemetal soldering, correcting castings and correcting stupid designs that frankly should never have been manufactured in the first place!

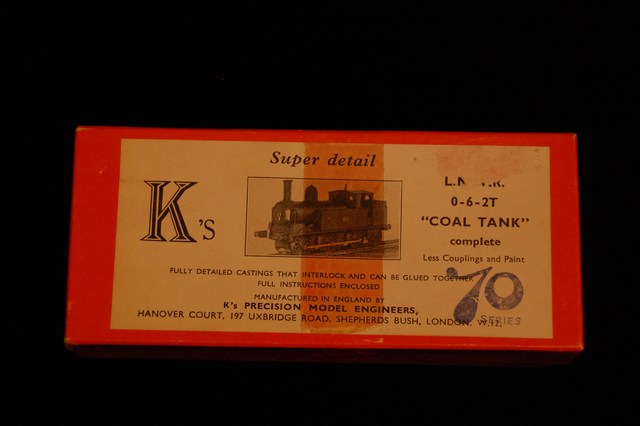

Some Time ago I received a very early K's LNWR coal tank.

Once you have built a few models, you open the box and can see instantly the bits that you know full well will never work and will invariably end up in the scrap box. For K's kits, the motors are almost always shockingly bad... the wheels are sometimes ok but more often than not they end up in the bin.... and you quickly learn that its really hit and miss weather the holes in the connecting rods will actually match up with the axle holes in the chassis!

When I opened this box, I could see it was an early motor. it actually didn’t look too bad. a bit basic by todays standards but could have been worse.

The wheels looked like they were worth a go...

But more importantly, many of the castings actually looked pretty good.

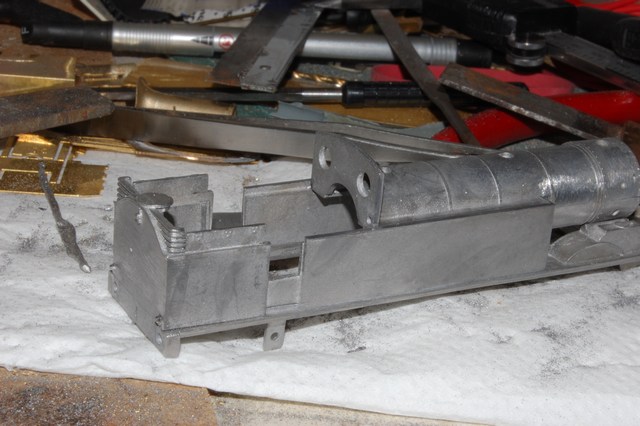

Basic construction of the body went pretty painlessly to start with...

Until I noticed a problem with the cab sides. The trouble was obviously with the masters rather than the castings themselves, but one of them was about 3mm behind the other!

The result of this was that the cab front would have sat wonky and the boiler wouldn’t have butted up neatly against it.

What followed was the most careful sawing exercise I have ever done! With a brand new razor saw, I very carefully cut the cab sides from the top of the side tanks. The razor was cuts a slot about 4 thou thick. this was very important as I knew I would have to reattach them later!

After that task, the bodyshell went together pretty easily.

The next task was the chassis. I didn’t hold out too much hope for many of the components, but initially I was encouraged to find the connecting rods and axle cut-outs were an exact match!

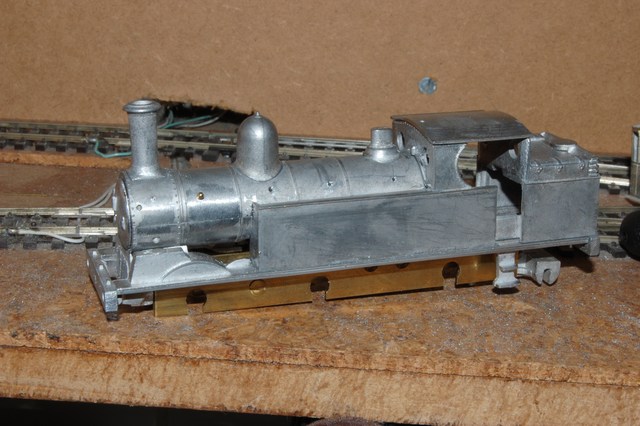

I tried the original wheels and all was going well until the time came to pump some electricity though the 1970's motor...

it ran beautifully for about 5 seconds before grinding to a halt and going puff! the smoke wasnt too bad and not entirly unexpected but not exactly welcome!

I tried to carefully remove the wheels as they wernt too bad, but alas thay were stuck on with loctite and were going nowhere.

So phonecalls went in to High level for a new gearbox/motor and Gibson for a new set of wheels.

After that, it all went smoothly.

It always makes me wonder how many people were put off kit building, not because their skills were not up to scratch, but because of the poor quality of some of the kit components.

These days we have the option of some very nice gearboxes and motors. but in the 1970's when this loco was produced, you were really stuck with what came with the kit! The problem with the cab sides wasnt a particularly big deal, but that was simply because I had the tools and patience to deal with it. If I was new to kit building it would have been a different story.

This was the first loco that I lined by hand. the lining is not wonderfull but I was reasonably pleased with it.