It never ceases to amaze me how many kits get purchased and never even started.

I estimate that only 1 in 10 even get started.

Having said that, I am only in my early 30s and already I have got a pretty good selection of about 20 kits sitting in the cupboard waiting to be done. This is not so much a bad case of retail therapy, but a serious necessity brought about by the way this industry works. Over the years I have lost track of the number of small cottage industries that have disappeared since I started modelling more seriously.

People often don't realize that many of these businesses are one man businesses and often run by people already advancing in years!

Its really not unusual to have a proprietor die one day and the range of kits they produced is never seen again! or for a proprietor to retire and suddenly finds out that his range is really not worth what he thought it was worth so decides not to sell.

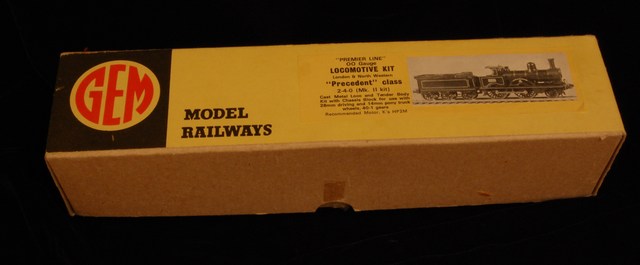

It was a nice surprise to have a GEM Precedent land on my workbench. 35 years after it was produced!

After an initial look at the castings, things were a bit of a mixed bag.

The motor was certainly past its use by date - technology has just moved on.

Someone had made a start with the kit using epoxy resin to stick it together. The tender was stuck together as was the 2 halves of the boiler. The instructions were actually pretty good with a nice exploded diagram to work from. I must admit that I rarely actually read instructions. After you have built a few, you know the score!

All of the parts basically fitted and after pulling apart the glued joints and soldering them it began to look like a proper loco. I used the vast majority of parts in the box exactly as intended. The GEM kits have gone through several generations since George E. Mellor first produced them and the quality of the kit is very much dependent on who was the proprietor at the time!

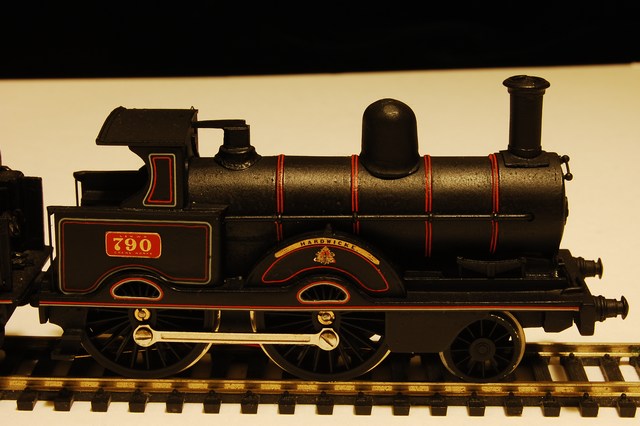

The tender got a waft of paint. I find that a light coat of a dark color is very good for showing up imperfections that need filling before applying the final top coat.

The top coat was LNWR blackberry black. I almost exclusively use Phoenix Precision paints. A rather beautiful color. Almost completely black but with the tiniest hint of blue that only comes out under certain linghting conditions or when you catch it at just the right angle!

Most of the lining was from the HMRS transfers sheet. I actually prefer waterslide decals and tried to use Fox waterslide transfers for the boiler bands. But I found that the lines were just too think and it looked a bit silly. It didn't take me long to realize it couldn't stay like that and they had to come off. I finally settled on using the pressfix transfers from the same sheet as the rest of the lining.

Nameplates were a complete pig! they were only etched on a single side meaning they had to be very carefully filed from the sheet.

I had a fascinating conversation with someone about this loco. There are some reports of them putting in extraordinary performances in their early life. and some reports of them exceeding 100mps. I must admit to being a little sceptical. but it was pointed out to me that at the time, the quality of coal used was extremely high and the the drivers were highly skilled at getting the most from their locos.

For the record, the motor was my standard solution of a Mashima 1024 with a High Level 108:1 gearbox and a flywheel. This almost always gives a nice smooth runner.

Most of the locos I build tend to be big passenger engines. Its a nice change and very rewarding to produce this little GEM. It looks beautiful when running with 4x Ratio LNWR coaches.